The first article in The Kelp Revolution: Our Seaweed Series

“Time forks perpetually toward innumerable futures. In one, you buy your kelp salad in a kelp-plastic package and drive it home in a kelp-powered car.”

– Stefan Milne

According to Global Market Insights, the commercial seaweed market was valued at $59 billion in 2019, and is expected to grow to over $85 billion by 2026. Seaweed is a staple of several Asian cuisines, and shows up on plates in other parts of the world. However, the growing seaweed market is also driven by seaweed’s many uses in key industries. . Kelp can grow multiple feet per day, and more and more people are starting to farm it. As a quickly growing, low resource crop, seaweed is all around us. Compounds extracted from seaweed are in many of our foods, and it is being added to livestock feed. In fact, seaweed is already an ingredient in many consumer products we use every day, and it is on its way to replacing others. Industry experts and seaweed superfans advise that a “Seaweed Revolution” is coming. I think this revolution has already begun.

This series will explore seaweed’s uses in our society, how seaweed can mitigate climate change and the commercial seaweed industry itself. This first installment will focus on seaweed’s role in creating the products we rely on.

Carrageenan, Agar, and Alginate – Secret ingredients

What do almond milk, toothpaste and moisturizer all have in common? They all include a key compound extracted from seaweed. Many species of red seaweeds contain high concentrations of a chemical compound called a polysaccharide. Seaweed polysaccharides add a gel-like texture by increasing viscosity, giving them a wide variety of culinary and industrial uses. The three most common types of seaweed polysaccharides are carrageenan, agar, and alginate.

Carrageenan is used widely in dairy products, jellies, and even meat products. The inclusion of carrageenan makes these foods creamier, gives them a better mouth-feel, and helps them remain stable when defrosted. Carrageenan also enhances the texture of personal hygiene products. Carrageenan is a sustainable option for thickening toothpaste, often used instead of a synthetic thickener or an animal-based thickener such as gelatin. This versatile seaweed extract is also added to moisturizers, soaps, and shampoos to optimize texture.

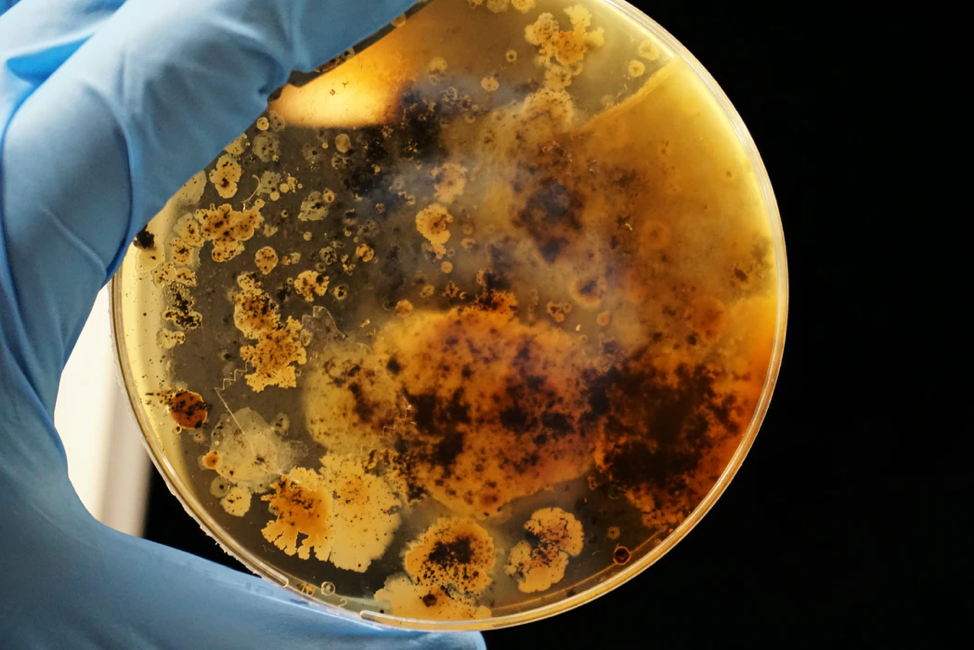

Agar is beloved by biotechnologists and other researchers who use the compound to create a cell culture media in which to grow bacteria. Agar is an ideal gel for growing bacteria because, unlike other viscous compounds such as gelatin, the agar itself will not be eaten by the bacteria. Scientists can add other nutrients to the agar, and create a stable, nutrient-rich medium in which the bacteria can grow. Agar nutrient plates have become indispensable to medical research, bacteria culture and testing, and cell assays.

Alginate is often transformed into a compound called sodium alginate. In the textile industry, sodium alginate is used to thicken fabric dyes so they can be easily applied to fabric. Alginate is also used to provide an antibacterial finishing layer to textiles. Theanne Schiros, a professor at the Fashion Institute of Technology in New York City, suspects that alginate gel could be “extruded into long strands of fiber that can be woven into a fabric.” Schiros and her team are researching the feasibility of algae-based, biodegradable yarn. Perhaps seaweed will help bring about the end of fast, environmentally harmful fashion.

A sustainable alternative to plastic

Seaweed is also starting to replace single-use plastics. Several companies around the world are working to produce seaweed bioplastics at scale. Loliware’s first product, the Straw of the Future, is a compostable straw made from seaweed. According to the New York startup, the straw is made from 100% plant-based materials and can endure 18 hours of use. Oceanium, a UK-based seaweed production company, has developed Oceanware, a compostable, seaweed-based bio-packaging material. They source their raw material from sustainable seaweed farmers in the North Atlantic Ocean, bolstering demand for seaweed.

Some startups in the space are even using seaweed to make edible packaging. Notpla has created a product called Ooho, which is seaweed-based packaging for beverages and sauces. According to the company, Ooho “biodegrades in 4-6 weeks, or you can just eat it, making it ideal for on –the-go consumption.” Evoware, an Indonesian startup developing plastic-free alternatives, has a similar innovation. They have created edible cups made from seaweed, designed to replace disposable plastic cups. These startups are showing us an exciting new possibility: that seaweed has the potential to replace harmful plastic packaging with something zero-waste and nutritious.

All of these alternative plastics companies are still early on in their journeys, but they are poised for growth and already making a positive environmental impact.

You can be part of the Seaweed Revolution

Seaweed is here to stay. In the coming years, as seaweed innovators scale, and seaweed becomes a major part of our sustainable future, there will be more and more opportunities to buy seaweed-based products. For now, if anyone you know needs sustainably made straws or packaging, you should share the companies in this article with them.

Interested in learning more? Read the Seaweed Manifesto, published in 2020 by the UN Global Compact and stay tuned as we explore the Kelp Revolution together in this Seaweed Series.